Project Description

PMMA Microspheres for Pore-Forming Agents

Polymethyl methacrylate (PMMA) spherical micropowder is a new type of functional additive that can be used as a pore forming agent material added when making ceramic or metal products, which can help reduce the weight of the finished ceramic or metal product. By forming pores in the inner structure of ceramics or metals, the finished products not only have the texture of ceramic or metal materials but also has the advantage of being lightweight.

EPRUI Biotech Co. Ltd. can provide PMMA microsphere as powder form with particle sizes ranging from 3-100um according to specific needs to meet various practical application requirements.

EPRUI Biotech Trusted By

Specifications

PMMA Microspheres for Pore-Forming Agents Advantages

Our pore forming used PMMA microspheres is suitable for adding to various materials that need to form pores, such as porous ceramics, ceramic atomizers, molecular sieves, etc. In recent years, its scope of uses has been continuously expanded. PMMA microspheres can be added to vacuum chucks, ceramic suckers, ceramic atomizers, 3D printing materials, metal powder injection molding (MIM) materials, filter materials, catalyst carriers, etc., to reduce the weight of finished products.

1. Excellent high-temperature decomposition characteristics and strong compatibility with sintering processes

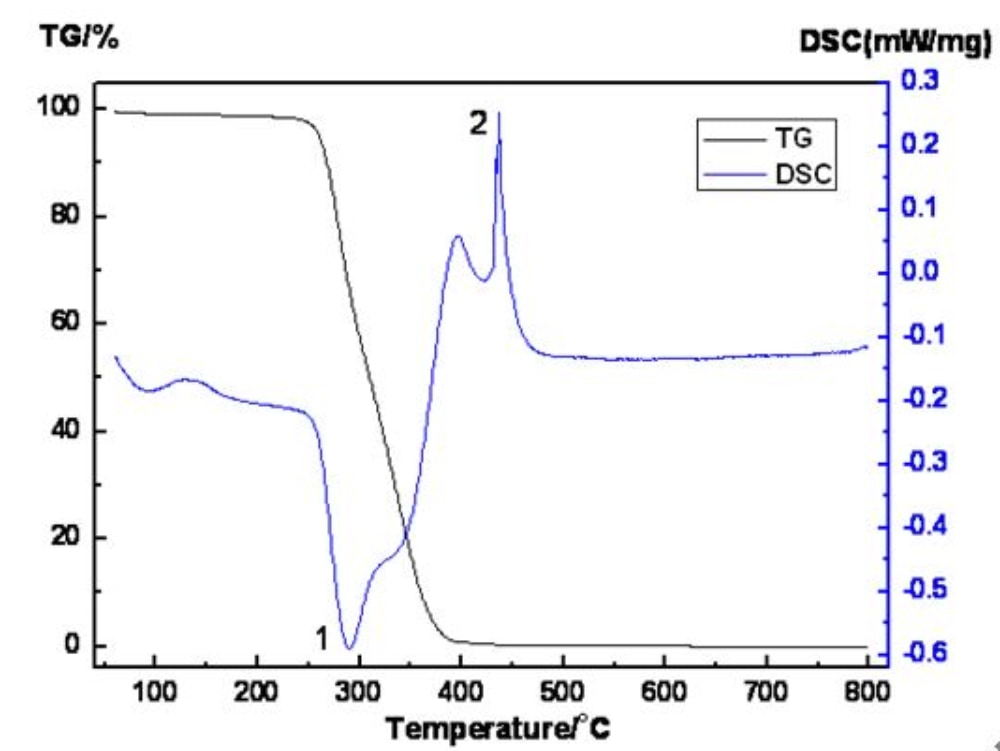

Controllable decomposition temperature: The decomposition temperature of PMMA microspheres is about 240-400℃, which is lower than the sintering temperature of most ceramics (such as alumina ceramics with a sintering temperature of 1500-1600℃). It can be completely decomposed before the sintering of ceramic green bodies, avoiding residual impurities or reactions with the ceramic matrix at high temperatures.

Mild gas release: The decomposition process mainly produces gases such as CO₂ and H₂O, with a stable release rate and no severe expansion or gas explosion. This reduces defects such as pore collapse and deformation inside ceramics, and is especially suitable for thin ceramic products (such as ceramic membranes).

2. Precise control of PMMA microsphere particle size

The precise control of PMMA microsphere particle size enables the precise control of the pore size of the end products with uniform pore structure. A variety of particle size specifications are available: 3μm, 5μm, 10μm, 15μm, 20um, 30um, 40um, 50um and other different particle sizes of PMMA microspheres for flexible regulation of pore size.

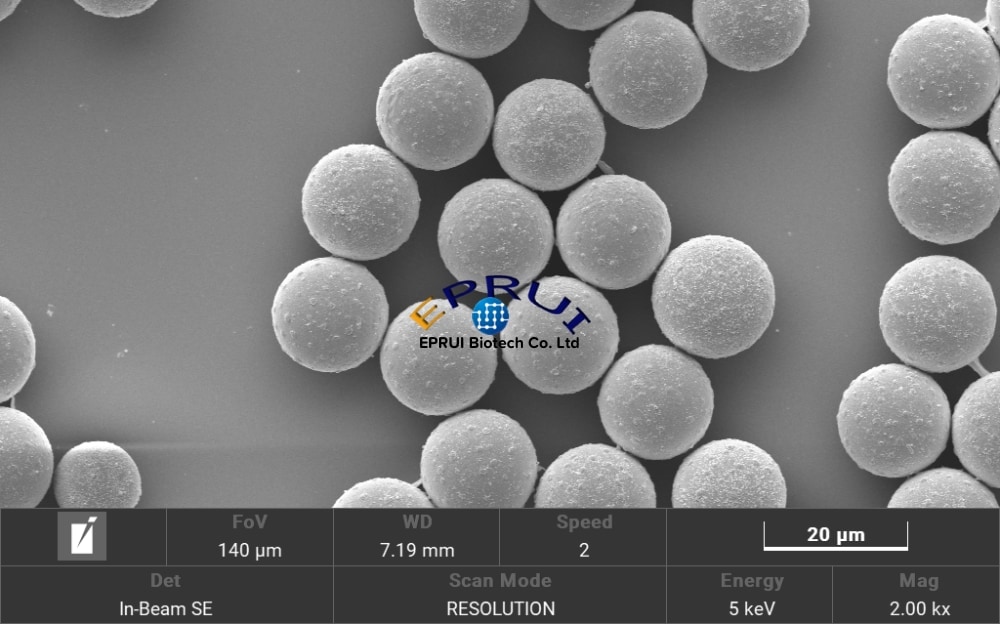

Uniform pore size distribution:Our monodisperse PMMA microspheres have uniform particle size and perfect spherical morphology. After being dispersed in the ceramic green body, the pores form after sintering and decomposition have uniform particle sizes, avoiding the problem of irregular pore sizes caused by particle size differences of traditional pore-forming agents. PMMA microspheres are especially suitable for filter materials and catalyst carriers which have strict requirements on pore structure.

3. Little impact on the mechanical properties of ceramics

Spherical PMMA particles used as pore formation agent create regular spherical pores. The pores formed after decomposition are mostly spherical and smooth pore walls. Compared with the sharp pores generated by irregular pore-forming agents (such as activated carbon), it can reduce stress concentration points which reduce the risk of ceramic cracking.

Low mechanical loss: Experimental data shows that the flexural strength retention rate of porous ceramics prepared by adding 10% PMMA microspheres can reach 70%-80% of that of dense ceramics while it is only 50%-60% if add traditional pore-forming agents such as ammonium carbonate). Therefore,PMMA microspheres pore forming agent is suitable for structural parts that need to balance porosity and strength (such as ceramic suckers and filter tubes).

4. Significant advantages in environmental protection and processing efficiency

Non-toxic and pollution-free: PMMA has strong chemical inertness, and the decomposition products have no irritating gases, meeting the requirements of environmental protection production. Compared with some organic pore-forming agents (such as polyvinyl alcohol), it is easier to pass environmental protection inspection.

Fast burnout rate: The PMMA of our company has been tested to decompose between 240℃ and 400℃ and completely decompose before 500℃, which saves sintering time compared with traditional pore-forming agents, improves production efficiency and reduces energy consumption costs.

5. Determine the pore structure and properties of ceramics when preparing porous ceramics

In the milling and mixing stage, PMMA microspheres’ features of uniform particle size and high sphericity can reduce the friction between ceramic powders, improve the fluidity of the mixture system, achieve uniform dispersion, and lay a solid foundation for the formation of regular pores. When adding organic binders for granulation and mold forming, PMMA microspheres act as “rigid fillers”. Their spherical structure can make the green body stress evenly, reduce the risk of cracking caused by stress concentration, and at the same time, cooperate with binders to enhance the forming performance of the green body, ensuring the precise forming of complex shapes.

Plastic removal is the core link for PMMA microspheres to exert their pore-forming function. When the temperature rises to 240-400℃, PMMA microspheres pyrolyze and volatilize. This temperature is much lower than the ceramic sintering temperature which avoids the sintering of ceramic particles. After volatilization, spherical pores consistent with the particle size of PMMA microspheres are left in the ceramic matrix, constructing the initial porous structure. In the final sintering stage, the ceramic powder is densified through atomic diffusion, and the pores formed by PMMA microspheres are completely retained. The porosity and pore size of ceramics can be precisely controlled by adjusting the addition amount and particle size of PMMA microspheres. For example, increasing the amount of microspheres can increase the porosity; selecting microspheres with different particle sizes can prepare porous ceramics suitable for different fields such as biomedical bone repair scaffolds and high-precision filters for filtration and separation.

6. How to order

Please send e-mail to: sales@epruibiotech.com or call us by 86-21-64192663 for products inquires.

For detailed steps, please visit: How to Buy